Competitiveness

Faced with ever stronger competitiveness, faster technological evolution and greater market demands, Quality improvement has undoubtedly been elevated to one of the industry’s top priorities.

SINFLEX, aware of this need, has as its main objective the launch of products on the market that satisfy its Clients, in terms of Quality, price, as well as delivery time.

Commitment

This commitment presupposes the existence of an environment in which everyone feels encouraged and motivated to fulfil the determinations imposed by the Quality Management System, so that together it is possible to achieve the company’s strategic objectives.

This effort is embodied by the close cooperation we develop with all our suppliers and customers, because, after all, we are stakeholders in a united growth.

Policy

SINFLEX’s Policy is clearly defined in its Management Manual, a document that defines the means and procedures that are adapted to ensure the appropriate quality of the products and services supplied.

Recognising the interdisciplinary nature of Quality Management functions and the dependence of the human factor in the pursuit of the stated objectives, it is the obligation of each of its employees to comply with and ensure compliance with the determinations contained in the Quality Management Procedures (Q.G.P.) and Work Instructions (I.T.), as well as to collaborate in all Quality improvement actions carried out by the company.

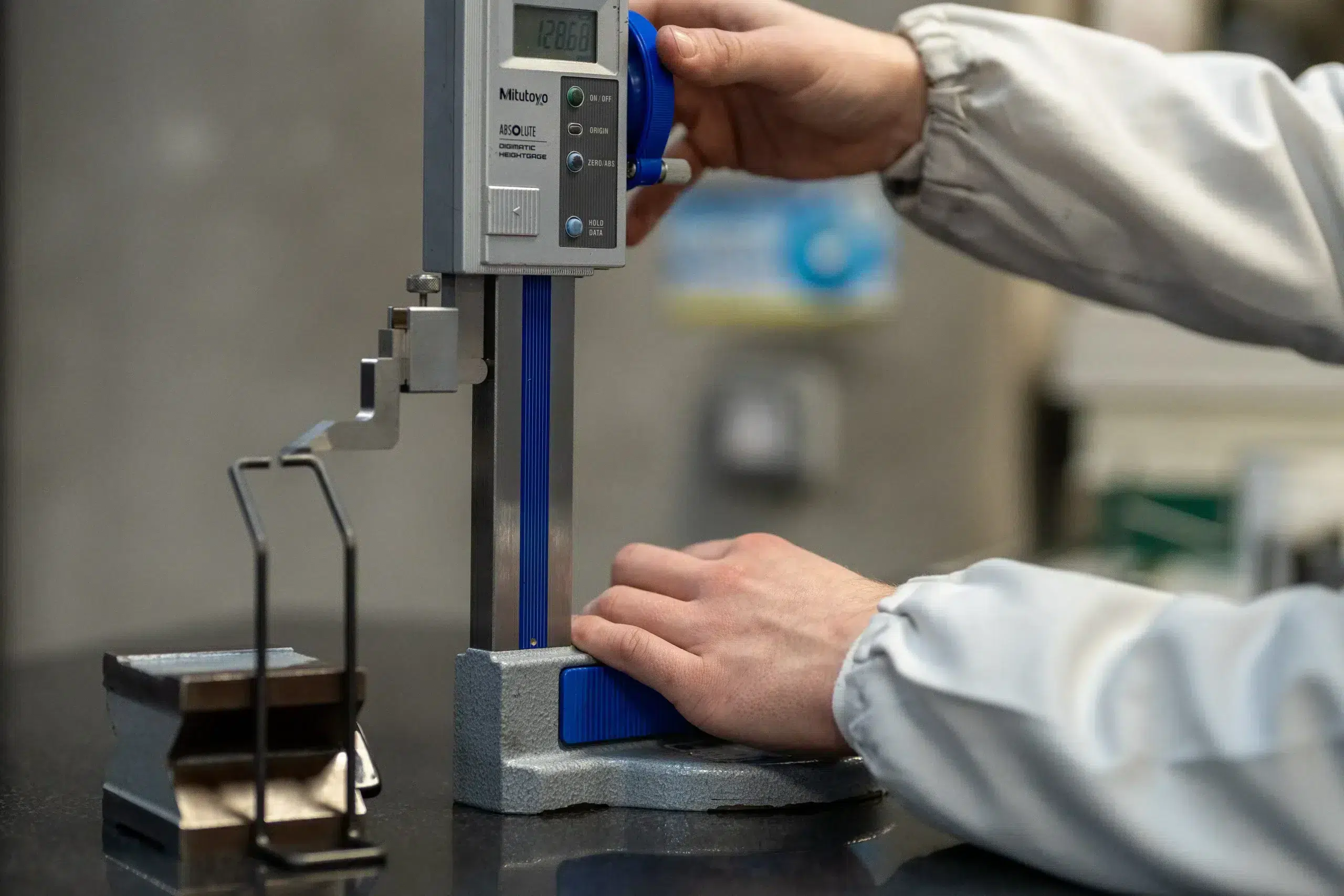

Laboratory

The SINFLEX Laboratory has all the necessary equipment to carry out control tests to support the production.

The policy defined in the Laboratory Manual has as its main objective the total satisfaction of the needs arising from SINFLEX’s production process. To this end, it establishes the following principles:

- To have technical and management staff with the authority and means necessary to perform their functions;

- To have staff members free from pressure or other undue influences;

- To ensure that staff members maintain professional secrecy;

- To ensure the protection of confidential information;

- Provide adequate support to the personnel carrying out tests.

Certifications

We have been a certified company since 1998 and, in 2009, we have strengthened the strategy we have been following of enhancing our technological capacities, certifying our QMS in accordance with the directives of the technical specification ISO TS 16949, geared towards the automobile components sector.